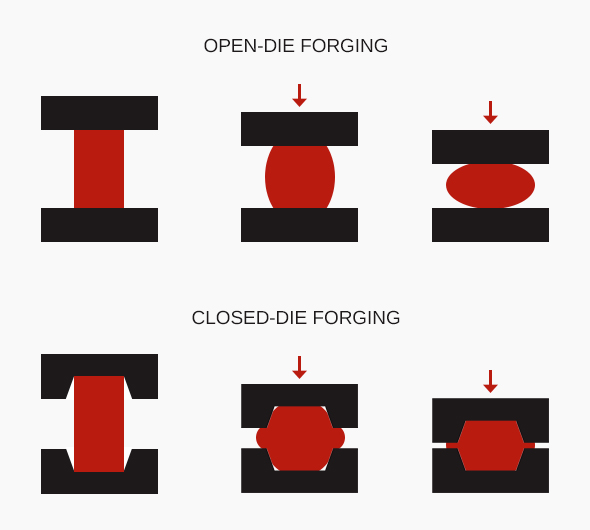

When it comes to contorting and deforming metal, there are multiple techniques that involve die forging. Two of these techniques are open die forging and closed-die forging. While both utilize the same basic processes of heating and deforming metal with calculated force, they differ when it comes to the actual die plates themselves.

Let’s explore the definitions, the forging process steps, differences and various pros and cons of each die forging process.

What Is  Open-Die Forging

Open-Die Forging

Open-die forging, also known as free forging or smith forging, is the process of striking a hammer to deform a piece of metal, typically placed on a stationary anvil. Another approach is to use compression to press the metal between simple dies. These simple dies are typically flat, semi-round or V-shaped. Regardless of the die shape, the metal is never completely encased in the open-die forging process. The dies hammer or press the metal through a series of repetitions, altering the material until achieving the desired shape.

Open-die forging is not recommended for complex shapes, and often requires precision machining and forging equipment to complete the process since the dimensions produced by hammering during the open die forge process can be imprecise.

Pros of Open-Die Forging

- Little or no tooling cost

- Reduced lead time

- A variety of size options, from a few centimeters to nearly 100 feet

Cons of Open-Die Forging

- Not suitable for forming intricate, precision parts or other close-tolerance applications

- Machining is often required to complete open-die forgings

- Process doesn’t always produce consistent results or desired features

What Is Closed-Die Forging?

Closed-die forgings, or impression-die forgings, involves metal being placed between one or more custom-shaped dies. The metal is hammered or pressed, causing it to flow and fill the shaped-die cavities.

Closed-die forging is one of the most commonly used methods for forging steel parts. This closed die forging process works with the metal’s internal grain structure and can produce stronger, longer-lasting products.

Little to no machining is needed for closed-die forgings. The closed die forging process simply utilizes the force from a closed-die forging hammer or press, and heat, to deform the metal to fill the die impression or mold.

The Advantage of Flash in Closed-Die Forging

Where both die forgings can result in a thin layer of flash (excess material squeezed out during the die forging process) the closed-die process uses the flash to its advantage. As the flash promptly cools, it increases pressure on the impression, which encourages the metal flash to flow into details/crevices. The excess flash is then manually removed.

Pros of Closed-Die Forging

- Better surface finish and superior mechanical properties

- Reduced or no machining

- Cost-effective for large production runs

- Dimensions with tighter tolerances and various shapes can be achieved

- More precise, consistent impressions

- Ability to reproduce nearly any shape and/or size

Cons of Closed-Die Forging

- Not typically economical for short or small production runs due to the cost of die production

- Higher setup cost due to costly machines and furnaces

Reach Out to Canton Drop Forge for Closed-Die Forgings

If you think your production can benefit from closed-die forging, we can help. Canton Drop Forge is a leading developer and manufacturer of closed-die forgings for high-performance applications. We have more than 100 years of impression-die forging experience in a variety of forging markets all over the world. To see how Canton Drop Forge can provide precise custom forging solutions for your industry’s needs today, contact our forging experts.