Power generation of any kind requires two very important things — qualified professionals to handle the job and powerful equipment and materials that can withstand intense working environments. Because of their hot conditions, power plants with steam turbines are no exception to that rule. It is crucial that all components used can hold up when extracting steam.

That’s where Canton Drop Forge can help. As a leader in custom forged products for markets ranging from the military and defense industry to transportation, Canton offers one-of-a-kind steam turbine blades that are personalized to each client’s specifications.

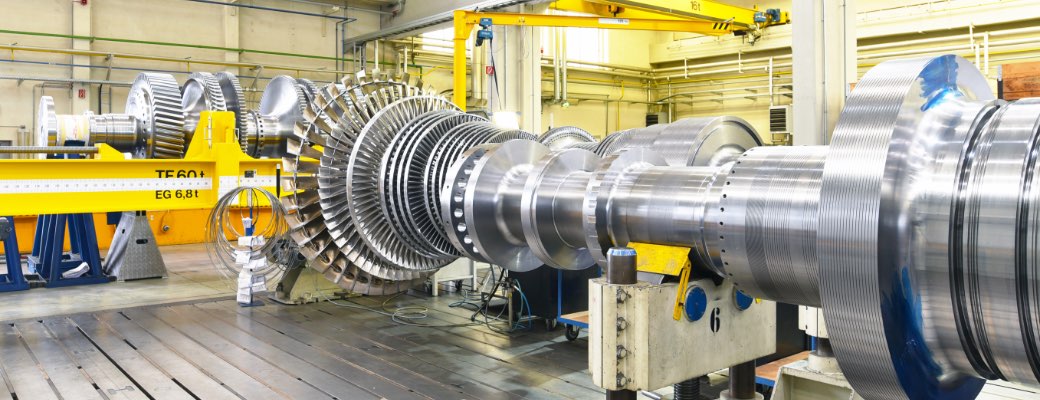

How Our Forged Turbine Blades Handle Steam Turbine Challenges

Steam turbine operations are intense, and every turbine blade is subjected to high temperatures and physical stress. If a blade isn’t properly designed for extreme heat, the heat can damage it over time and eventually cause a deformation called creep. To avoid this, steam turbine blades must be applied with specific thermal coatings to strengthen the blade. Steam turbine blades can also undergo erosion or corrosion in two different ways — oxide scales at the front of the turbine and droplets of water at the back.

Steam Turbine Blade Manufacturing Company

Canton Drop Forge is aware of these challenges and we strive to construct each turbine blade with the materials needed to avoid any complications. Our goal is to ensure that every power plant we work with is well-equipped with steam turbine blades that will last for many years to come.

See the Difference in Our Forged Steam Turbine Blades

At Canton Drop Forge, we’re proud to produce some of the most valuable forged turbine blades for the power generation industry. When it comes to steam power plant operations, efficiency and safety are key, and we guarantee that our steam turbine blades will provide just that. If you’re ready to learn more about how our forging capabilities can vastly improve your workflow, contact us today to get your free quote. We look forward to working with you!