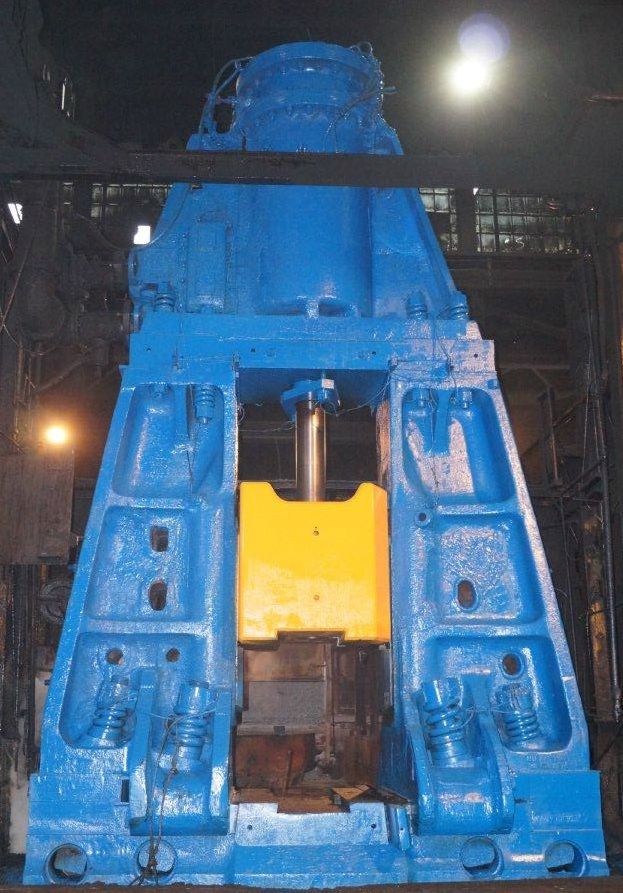

Our Forging Hammers

Our forging equipment & capabilities include 14 hammers designed to handle projects of any size, working with metals such as carbon alloy, stainless steel, and high-temperature alloys.

- 1-3,000 lb

- 1-5,000 lb

- 1-10,000 lb

- 1-14,000 lb

- 1-18,000 lb

- 3-20,000 lb

- 3-25,000 lb

- 2-35,000 lb

- 1-50,000 lb

Additionally, our 1200-ton hydraulic press is ideal for trimming and open-die processing, expanding the versatility of our metal forging equipment.

Heat Treatment

Canton Drop Forge boasts industry-leading heat treatment facilities, including continuous oil and polymer quench lines as well as Nadcap-certified furnaces for annealing, normalizing, and tempering. Heat treatment forging equipment is an integral process we provide for our partners.

Our heat treatment capabilities include:

- 3 Continuous Normalize, Temper, or Anneal Furnaces

- 2 Continuous Hardening and Drawing Furnaces with Oil and Polymer Quench Tanks

- 2 Batch-Type Nadcap-Approved Normalizing and Tempering Furnaces

These advanced processes ensure durability and precision in every part we produce.

Complete Die-Sinking

Precision is at the heart of our operations. Our in-house die sinking capabilities allow full control over the creation of complex forge tooling. With four large CNC mills and multiple Vertical Turning Lathes, we deliver exceptional results for every project.

Partner With Canton Drop Forge Today

With cutting-edge forging tools and equipment, and decades of expertise, Canton Drop Forge is the partner you can trust to deliver exceptional results. From die sinking and heat treatment to forging hammers capable of handling the toughest materials, we provide the capabilities, experience, and precision your project demands.

Contact us today to discuss your part requirements and discover how we can exceed your expectations. Get started now and ensure your project is completed on time and within budget!