Why Stainless Steel Forging Outperforms Other Methods

When strength, corrosion resistance, and heat tolerance are non-negotiable, forged stainless steel provides unmatched performance and quality for projects. Unlike common casting or machining, forging stainless steel refines the grain structure, enhancing toughness, fatigue resistance, and overall durability—which is why it’s the preferred choice for critical applications across industries.

Stronger and More Reliable Than Cast or Machined Parts

Compared to cast or machined steel, forging produces a tighter grain structure, reducing its porosity and eliminating the weak points. This results in higher tensile strength, fatigue resistance, and impact toughness, making forged stainless steel the superior choice for parts subjected to mechanical stress or harsh conditions.

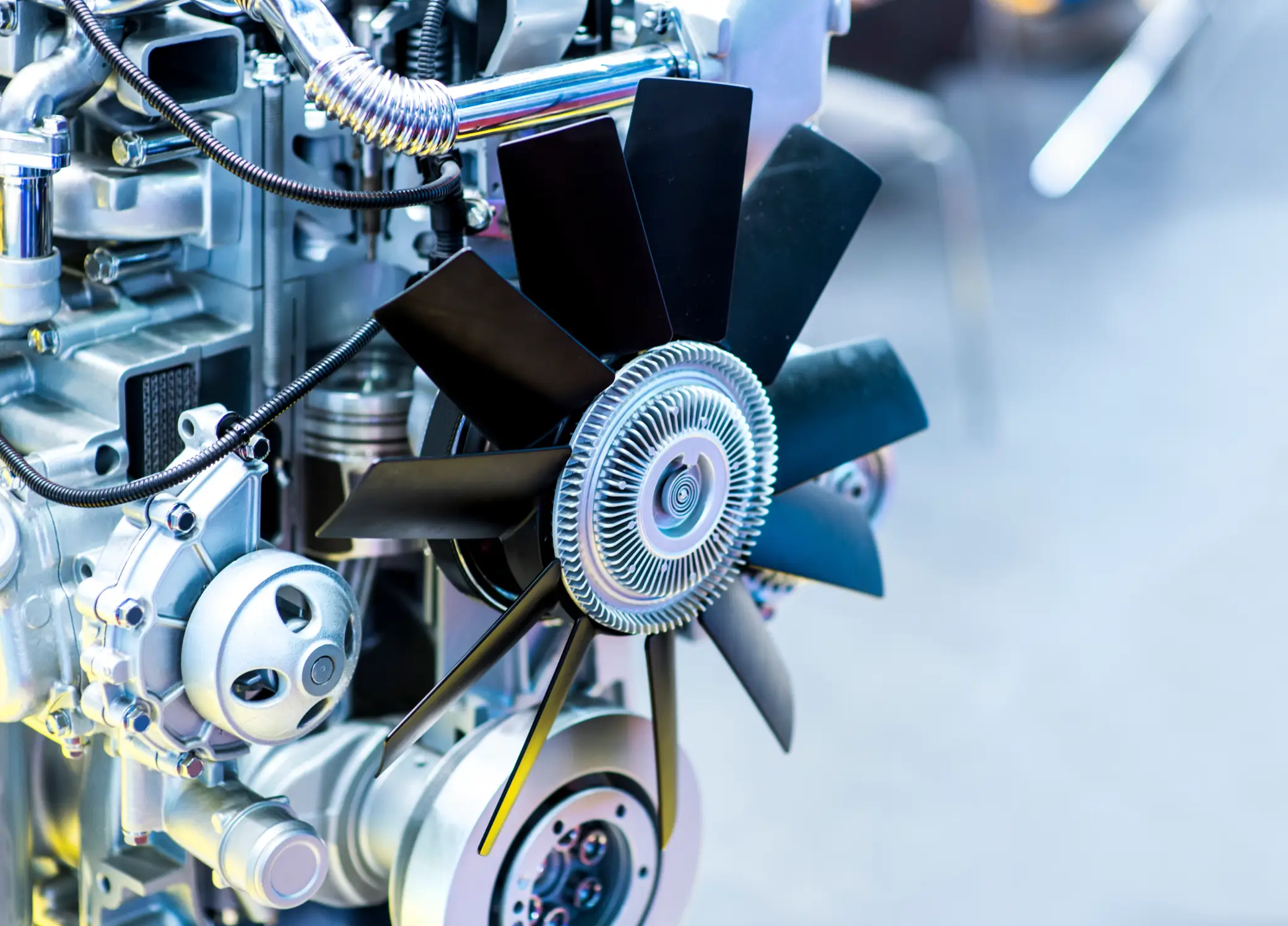

Exceptional Corrosion and Heat Resistance

Industries like aerospace, power generation, and transportation all require materials that can withstand oxidation, extreme temperatures, and corrosive environments. With its inherently high resistance to rust, scaling, and chemical exposure, stainless steel forging ensures long-term performance in conditions where other metals fail.

Cost-Effective and Long-Lasting

While forging stainless steel may have a higher initial cost than alternative methods, it reduces the need for secondary machining and extends the service life of components. Fewer replacements and lower maintenance costs make it a cost-efficient solution for high-performance applications.

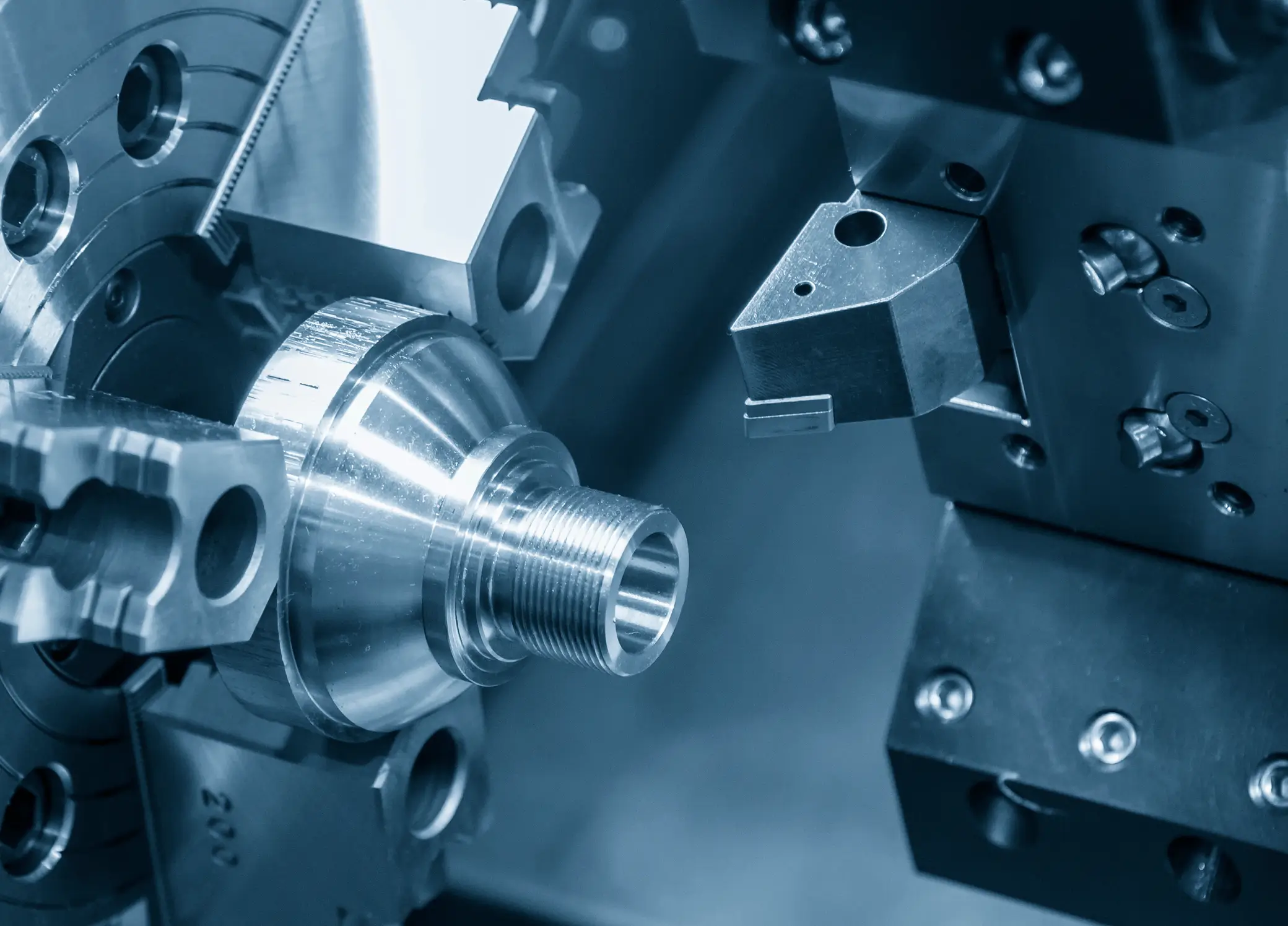

Precision Forging Across a Range of Stainless Steel Grades

At Canton Drop Forge, we specialize in forging stainless steel components that stand up to high-stress environments, extreme temperatures, and corrosive conditions. Because of our decades of expertise, we’re capable of forging a variety of high-performance stainless steels, each suited for specific industrial applications.

300 Series Stainless Steel (Austenitic)

300-series stainless steels, known for exceptional corrosion resistance and high toughness, are widely used in marine environments, aerospace components, and food processing equipment.

Common grades:

- 304 Stainless Steel – Excellent oxidation resistance and durability, ideal for pumps, valves, and chemical processing equipment.

- 316 Stainless Steel – Enhanced resistance to chlorides and acids, making it a top choice for marine, pharmaceutical, and medical applications.

400 Series Stainless Steel (Martensitic & Ferritic)

400-series stainless steel offers higher strength and wear resistance than austenitic stainless steel, making it a preferred choice for high-stress structural components, industrial machinery, and power generation equipment.

Common grades:

- 410 Stainless Steel – Superior hardness and abrasion resistance, used in turbine blades, fasteners, and high-temperature applications.

- 420 Stainless Steel – Higher carbon content for increased hardness, often found in cutting tools, pumps, and industrial shafts.

Duplex Stainless Steel

A balanced combination of austenitic and ferritic structures, duplex stainless steel provides twice the strength of 300-series alloys while maintaining excellent resistance to corrosion, stress cracking, and pitting. Duplex stainless steel forged fittings and parts are used extensively in oil and gas pipelines, chemical processing, desalination plants, and offshore drilling applications.

We Forge to the Highest Standards

At Canton Drop Forge, quality isn’t just a checkpoint—it’s the foundation of everything we do. Forging stainless steel for high-performance industries requires precision, consistency, and adherence to the strictest industry standards.

Our Stringent Metallurgical Testing & Inspection

Quality starts with material integrity. Before we forge any stainless steel, our in-house metallurgical lab performs comprehensive testing to verify:

- Grain structure and refinement for maximum strength and fatigue resistance.

- Mechanical properties, including tensile strength, hardness, and impact toughness.

- Non-destructive testing (NDT) to detect internal flaws or inconsistencies.

- Chemical composition analysis to confirm compliance with alloy specifications..

Every forged stainless steel component is inspected using advanced ultrasonic, magnetic particle, and dye penetrant testing, ensuring zero defects before shipment.

Our Industry Compliance & Certifications

Canton Drop Forge meets or exceeds the strictest industry standards and holds many certifications, including:

- ASTM (American Society for Testing and Materials) – Ensuring material consistency and performance.

- ASME (American Society of Mechanical Engineers) – Compliance for pressure equipment and structural applications.

- AMS (Aerospace Material Specifications) – Precision standards for aerospace-grade stainless steel forgings.

- ISO 9001:2015 – Certified quality management system for process control and continuous improvement.

- Nadcap Accreditation – Advanced process validation for aerospace and defense applications.

See the Strength of Stainless Steel Forging in Motion

Want to see Canton Drop Forge’s expertise firsthand? Watch our video to explore how our precision forging process, advanced equipment, and metallurgical expertise come together to produce high-performance stainless steel forgings built for strength, durability, and extreme environments.

Frequently Asked Questions: Forging Stainless Steel

For more insights into forging stainless steel, explore our FAQ, where we answer the most common questions about our process, materials, and capabilities.

What are the key advantages of forging stainless steel over welding?

Forging creates a stronger, more uniform grain structure throughout the material, while welding introduces heat-affected zones that can weaken certain areas. Additionally, forged stainless steel components retain their original mechanical properties better than welded parts, which may require additional post-processing to restore strength.

What industries require forged stainless steel over other materials?

Industries that deal with high pressure, extreme temperatures, and corrosive environments rely on forged stainless steel. These include chemical processing, offshore drilling, medical equipment, and nuclear energy—applications where precision and durability are non-negotiable.

Can forged stainless steel be heat-treated for additional strength?

Yes, certain grades of forged stainless steel—especially martensitic and precipitation-hardening stainless steels—can undergo heat treatment to further enhance their hardness, wear resistance, and tensile strength. Austenitic stainless steels, however, typically rely on their natural work-hardening properties rather than heat treatment.

Let’s Forge a Solution—Talk to Our Stainless Steel Forging Experts Today

When performance, strength, and corrosion resistance matter, forged stainless steel is the solution—and Canton Drop Forge has the expertise to deliver. Whether you need precision-engineered fittings, structural components, or high-performance parts, our team is ready to tackle the most demanding applications. Let’s talk about your project and develop a forging solution that meets your exact specifications.

Get in touch today to discuss your requirements!