Closed-Die Nuclear Forgings

Nuclear power demands parts that stand up to blistering temperatures, punishing radiation, and relentless pressure cycles day after day, decade after decade. That’s the world Canton Drop Forge lives in. Leveraging 120-plus years of closed-die expertise, we turn specialty alloys into mission-critical nuclear forgings with repeatable accuracy and full regulatory traceability.

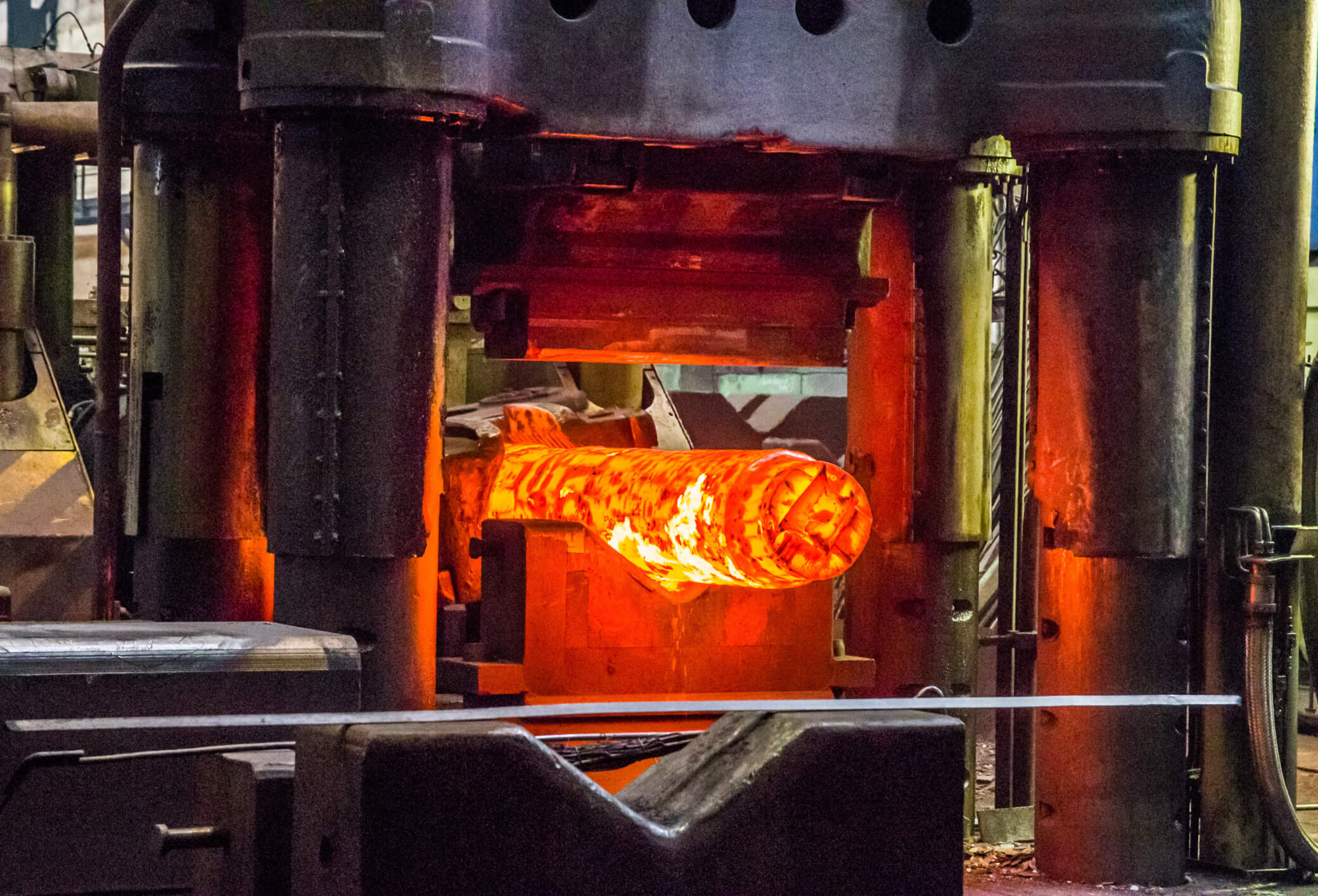

Our engineers partner with you early, optimizing every dimension for strength and manufacturability. Then our 1,200-ton hydraulic press and massive steam hammers translate the design into reality, whether you need primary pressure-boundary hardware, turbine rotors, or forged Inconel parts. Each piece exits the shop with complete NDT documentation, AS9100/ISO 9001 credentials, and the confidence that only a seasoned Inconel forging company can provide.

Ready to put uncompromising metal between you and the reactor core? Let’s talk about your next nuclear forging project; request a quote today.

REQUEST A QUOTE, TALK TO AN EXPERT

Forging for Heavy Manufacturing Applications such as Nuclear Forging

Our expert engineering and design, coupled with our world-class forging hammers and equipment, ensure your project is set up for success. Our engineers will help you save long term cost and prevent material waste. The strength and stability of your forged nuclear components are ensured through rigorous inspection and testing. Canton Drop Forge offers inconel forging for nuclear components and parts.

Inconel Forging for Nuclear Components

Inconel End Rings

Nuclear Component Parts

Full Compliance Guaranteed

Heavy Manufacturing

Reactor Manufacturing

Forging Hammer Capabilities for Carbon Alloy, Stainless Steel, & High Temperature Alloys

1200 Ton Hydraulic Press

Custom Nuclear Forgings You Can Trust

Every nuclear application is unique, and so is every forging we produce. At Canton Drop Forge, we specialize in custom nuclear forgings that meet the exacting demands of pressure-boundary components, reactor internals, and turbine assemblies. Whether you’re building new systems or supporting legacy infrastructure, our team works closely with yours to develop solutions that match your specifications, your timeline, and your compliance requirements. Every part starts with smart design and ends with tight tolerances, documented testing, and full material traceability.

When failure isn’t an option, you can count on nuclear forgings from Canton Drop Forge.

Forged Inconel Parts for Nuclear Components

When your components face heat, stress, and corrosive environments all at once, Inconel is often the only choice. As a trusted Inconel forging company, Canton Drop Forge delivers high-integrity forged Inconel parts engineered for the demands of nuclear power generation.

We forge a range of nickel-based superalloys, including Inconel® 600, 625, 718, and Incoloy® grades, to produce components that maintain strength and dimensional stability across decades of thermal cycling and radiation exposure.

Common applications for nuclear-grade Inconel forgings include:

- End rings and retaining hardware

- Guide sleeves and pump shafts

- Tube sheets and pressure-boundary flanges

- Control-rod drive housings

- Core support structures and tie plates

- & other nuclear components that can’t afford to fail

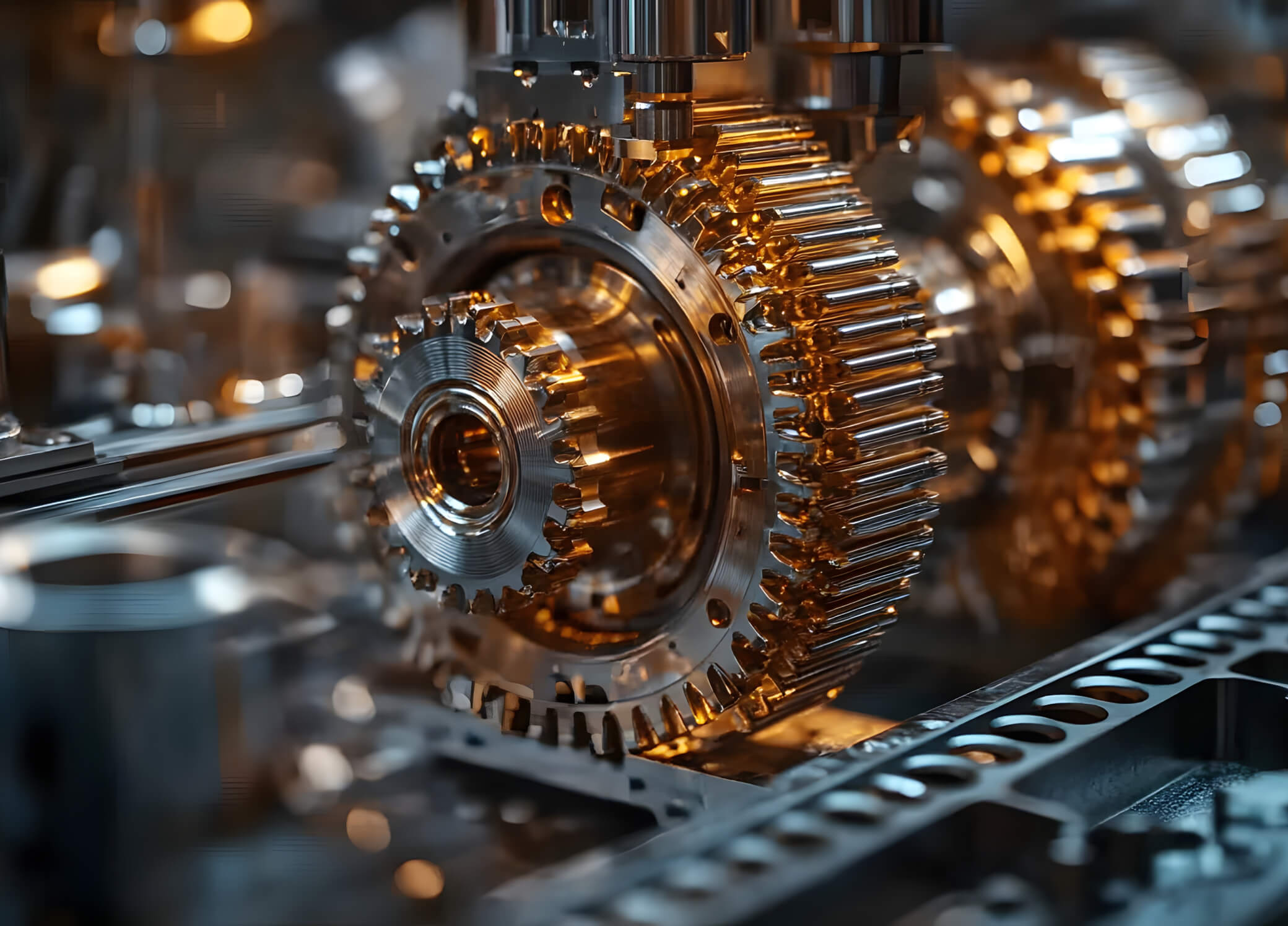

Forging Equipment for Demanding Nuclear Applications

Heavy-duty nuclear components call for equally heavy-duty tools. Our forging operation is equipped to handle complex geometries, oversized dimensions, and high-performance alloys with unmatched control and repeatability.

From massive pressure-boundary parts to intricate internal components, our equipment provides consistent results across a wide range of materials, including carbon and alloy steels, stainless steel, and high-temperature superalloys.

Our key capabilities include:

- 1,200-ton hydraulic press for consistent, controlled deformation

- High-capacity steam hammers; forgings up to 3,500 lbs and over 52 inches in length

- In-house heat treatment and die sinking for complete process control

- Advanced QA equipment with UT, MT, and PT non-destructive testing

- Precision machining and finishing to reduce post-forge waste and cycle time

With every project, our forging experts help optimize material usage, improve manufacturability, and minimize cost over the full lifecycle of your nuclear forgings.

Quality Assurance & Full Compliance

Nuclear power plants don’t get second chances, and neither do the nuclear forgings that keep them running. That’s why we embed quality into every stage of production, from the first spark of design to final shipment.

- Certified Systems: AS9100 / ISO 9001 quality management; Nadcap-approved metallurgy, heat treat, and NDT

- 100 % Non-Destructive Testing: Ultrasonic, magnetic-particle, and liquid-penetrant inspections verify internal integrity and surface soundness on every part.

- Full Material Traceability: Each bar, billet, and die is tracked through a digital traveler that documents chemistry, heat-treat cycles, and testing results.

- Tight Tolerances, Proven Repeatability: Statistical process control keeps dimensional deviations to a minimum, so your nuclear components fit and stay exactly where they belong.

- Documented, Ready-for-Review Records: You’ll receive a comprehensive data package that satisfies domestic and international nuclear codes, simplifying your own compliance documentation.

Whether it’s a custom flange, a pressure-boundary shaft, or a forged Inconel part destined for the reactor core, our quality assurance process ensures every component is built right.

Collaborative Engineering for Complex Military Components

Defense programs demand more than reliable hardware—they require a manufacturing partner who can engage early, adapt fast, and engineer with precision. At Canton Drop Forge, we provide full-spectrum support for custom defense forging programs, working alongside engineering teams, program leads, and procurement specialists from concept through production.

Our in-house engineering group brings deep experience in:

- Closed-die design and simulation, optimizing material flow and minimizing stress concentrations

- Reverse engineering of legacy or low-volume components, with full spec reconstruction when drawings are limited

- Collaborative prototyping for qualification runs, early-stage designs, and R&D initiatives

- Tooling development and rapid die production, enabling short lead times and responsive iteration

This engineering-first approach makes us a trusted partner in forging for the defense industry. Whether adapting to evolving Department of Defense (DoD) requirements or supporting accelerated timelines, our team has the technical insight and flexibility needed to meet your mission-critical goals.

Partner with a Proven Inconel Forging Company

When the stakes are high, experience matters. Canton Drop Forge has been delivering reliable, high-performance forgings for over 120 years, including decades of trusted partnerships in the nuclear sector.

We combine deep metallurgical knowledge with world-class equipment, responsive engineering support, and the certifications your project demands. Whether you’re planning a new build, supporting long-term plant operations, or solving a one-off component challenge, we’re here to help you forge a smarter, stronger solution on time and to spec.

Frequently Asked Questions: Nuclear Forgings

Have questions about nuclear forging and what sets Canton Drop Forge apart? Explore these common inquiries to learn more about our capabilities, materials, and quality-driven approach.

Why is Inconel such a popular alloy for nuclear components?

Nickel-based superalloys like Inconel® 600, 625, and 718 keep their strength even when exposed to high heat and corrosive coolants. When you need forged Inconel parts that shrug off stress corrosion cracking and thermal fatigue, an experienced Inconel forging company like Canton Drop Forge delivers a reliable, long-term solution.

What sizes and tolerances can Canton Drop Forge achieve for nuclear forgings?

Our steam hammers and 1,200-ton hydraulic press can forge parts up to roughly 3,500 lb (1,600 kg) and more than 52 inches in length. Typical machining allowances run ±0.020 in, while critical features on a nuclear forging can be held to ±0.005 in after finish machining and inspection.

What’s the typical lead time for custom nuclear forgings?

Lead times vary by alloy, die complexity, and qualification scope. A straightforward repeat order might run 8–10 weeks, while a first-article forged Inconel part that requires new dies and nuclear-grade documentation can take 16 weeks or more. Contact us early, and we’ll align the schedule to your outage or build timeline.

Let’s Talk Nuclear Forgings

Ready to get started? Contact us today to discuss your project requirements or request a quote. Let’s build something that lasts.