In the specialized realm of metal forming and manufacturing, closed die forging distinguishes itself as a premier technique, celebrated for its precision, performance, and unparalleled quality. At Canton Drop Forge, our commitment to excellence positions us at the industry’s forefront, providing tailored forging solutions that rigorously align with our client’s diverse and demanding specifications. Our deep dive into the intricate world of closed die forging not only showcases our extensive capabilities but also underscores the process’s inherent advantages, such as enhanced material strength, superior durability, and high precision in complex part production.

We leverage a broad spectrum of materials, from carbon and alloy steels to nonferrous metals like titanium, to cater to sectors as varied as aerospace, energy, and defense. Our state-of-the-art technology and engineering expertise allow us to deliver parts with tight tolerances and excellent mechanical properties, critical for applications where failure is not an option. Furthermore, our commitment to innovation and quality sets us apart in the forging industry, enabling us to develop solutions that not only meet but exceed the most stringent international standards.

This blog aims to illuminate the benefits and applications of closed die forging, diving into technical aspects such as die design, material selection, and the forging process itself. By exploring these facets, we aim to provide a comprehensive overview of how Canton Drop Forge remains a key player in advancing the forging industry, driving improvements in quality, efficiency, and customer satisfaction through our dedicated approach to craftsmanship and technological advancement.

The Essence of Closed Die Forging

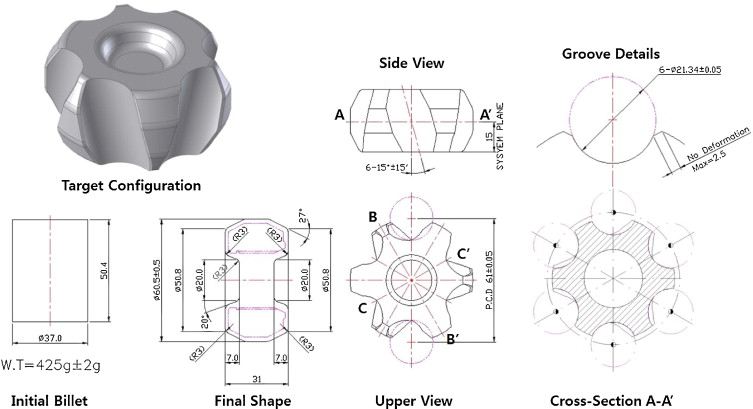

At the heart of metalworking innovation, closed die forging, also renowned as impression die forging, is a pivotal process that intricately shapes heated metal billets between two meticulously designed dies, mirroring the exact contour of the intended part. This method showcases versatility across a broad spectrum of metal materials, including alloy steels, carbon steels, stainless steels, aluminum, and titanium, making it a cornerstone technique in the forging industry. Closed die forging is celebrated for its capacity to minimize machining needs, deliver a superior surface finish, and bolster structural integrity, surpassing alternative forging and metalworking methods.

Canton Drop Forge’s unwavering dedication to mastering closed die forging is demonstrated through our sophisticated approach to creating precision components. Our state-of-the-art equipment, detailed on our capabilities page, enables us to tackle complex geometries and specifications, ensuring that each component we forge meets the stringent standards required by critical industries. From the high demands of aerospace engineering, where durability and weight are paramount, to the relentless pressures of power generation systems and the rigorous specifications of defense applications, our expertise in closed die forging facilitates the production of parts that are not only precise but also possess enhanced mechanical properties and reliability.

Advantages of Closed Die Forging at Canton Drop Forge

Our process leverages the intrinsic advantages of closed die forging by integrating advanced technology with over a century of accumulated expertise, as reflected in our comprehensive suite of forging equipment and capabilities detailed on our website. This approach enables us to offer unparalleled benefits in the manufacturing landscape.

The advantages include:

- Precision and Consistency: Our arsenal of state-of-the-art forging equipment, including precision hammers and presses, underpins our capacity to deliver forgings that consistently match the last in quality and specification. This ensures that components for high-performance applications meet the exacting standards required, reflecting our commitment to reliability and excellence.

- Material Efficiency: The efficiency of our closed die forging process is further evidenced by its ability to minimize material wastage. By precisely shaping metals to near-final dimensions, we significantly reduce the need for excess material and subsequent machining, positioning our operations as both economically and environmentally advantageous.

- Strength and Durability: Through the strategic manipulation of metal grain structure within our closed die forging process, we enhance the inherent mechanical properties of our products. This results in components that offer superior strength and toughness, qualities that are indispensable for parts exposed to rigorous operational demands.

- Customization: Our capability to produce custom forgings is supported by our advanced design and manufacturing technologies. This allows for the creation of complex shapes and designs that cater to the specific needs of diverse industries, from aerospace and defense and energy sectors. Our ability to adapt and tailor solutions underscores our dedication to meeting the unique challenges presented by our clients.

Our Expertise and Capabilities

Our Expertise and Capabilities at Canton Drop Forge extend into every facet of closed die forging, showcasing a robust array of services from engineering and design to rigorous inspection and testing of forged parts. We cater to diverse markets, leveraging our comprehensive suite of state-of-the-art forging hammers and hydraulic presses, capable of handling a wide range of metals including carbon alloy, stainless steels, titanium, and high-temperature alloys. Our heat treatment capabilities, featuring continuous and Nadcap-certified furnaces, alongside precision in-house machining for die sinking, underscore our commitment to delivering components that meet the highest quality standards. For more information, please visit the Canton Drop Forge equipment capabilities page.

Conclusion

The art of closed die forging is complex, requiring a delicate balance of skill, technology, and experience. At Canton Drop Forge, we have mastered this balance, offering our clients unparalleled precision, performance, and quality. Our dedication to advancing our capabilities and services ensures that we remain at the cutting edge of the forging industry, ready to meet the challenges of tomorrow. Whether you require high-performance aerospace components, durable mechanical parts, or any custom forging solution, we are equipped to exceed your expectations. Join the ranks of satisfied clients who trust Canton Drop Forge for their most critical forging needs.

For more information on our capabilities and to see how we can assist with your forging requirements, visit our website or contact us directly. We are ready to forge the future together, delivering components that drive industries forward.