What Are Forging Materials?

When crafting precision components, choosing the right forging materials is just as critical as the forging process itself. The properties of each material—such as strength, heat resistance, and corrosion resistance—directly influence the performance and durability of the final product.

Forging materials range from carbon and alloy steels to brass, copper, and high-temperature alloys containing elements like cobalt, nickel, and molybdenum. Each material brings unique characteristics to the table, making it well-suited for specific applications:

- Stainless steel offers unmatched durability and resistance to extreme heat and corrosion, making it ideal for marine equipment, gas turbines, and pumps.

- Carbon alloys provide affordability and excellent mechanical properties for automotive, oil and gas, and high-pressure piping systems.

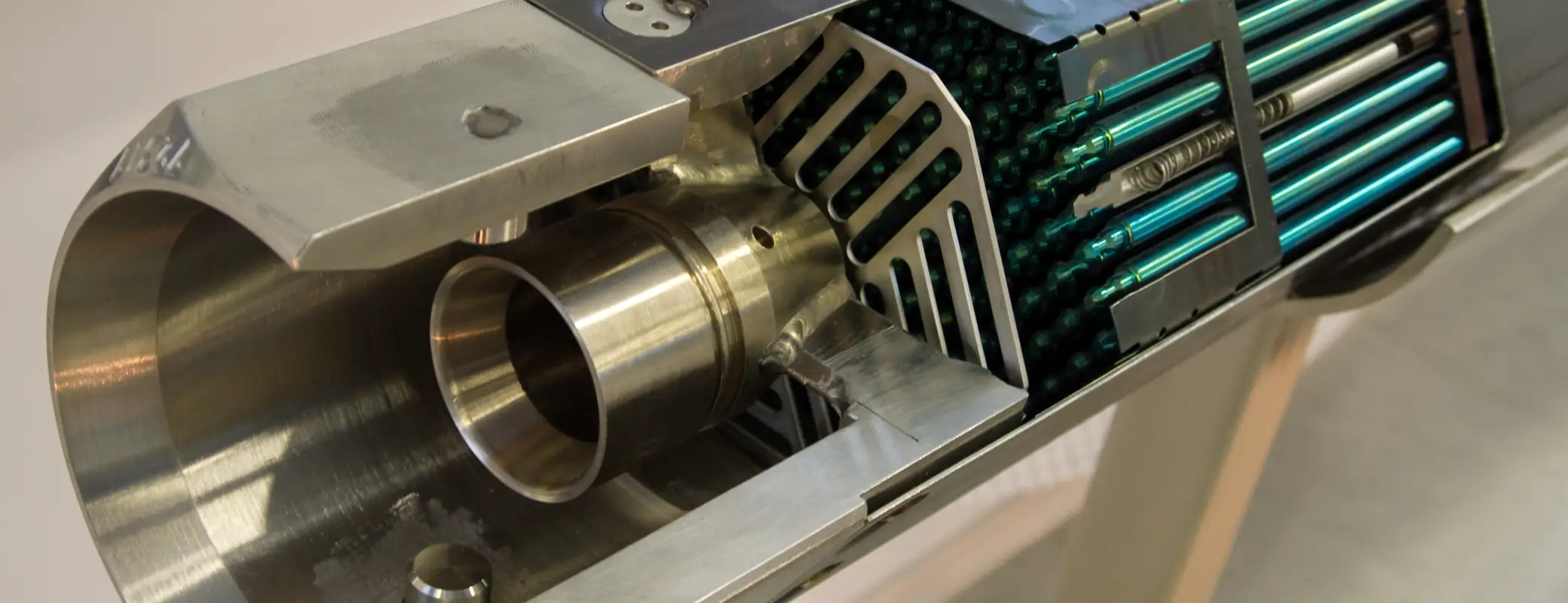

- Superalloys, with their ability to withstand extreme heat and maintain strength, are the go-to choice for turbine engines, solar thermal plants, and nuclear reactors.

The decision to use specific materials for forging isn’t one-size-fits-all—it’s based on the demands of your industry and application.

Common Forging Materials and Their Applications

At Canton Drop Forge, we deliver components that meet the most demanding requirements. Let’s take a closer look at four of the primary industrial forge materials we work with and why they excel in high-performance applications.

Stainless Steel

Stainless steel is the material of choice for forging metal components exposed to extreme heat, pressure, or corrosive environments. It is most commonly needed for industries like power generation, oil and gas, and aerospace, where reliability under harsh conditions is critical.

Key Characteristics:

- Corrosion-resistant and highly durable.

- Exceptional heat resistance, handling up to 1,250°F in high-stress environments and up to 1,800°F in low-stress conditions.

- Nickel-based alloy with superior strength and stability.

Carbon Alloys

Carbon alloys are versatile and cost-effective, making them ideal for a wide range of industries. These forging metals are commonly used in oil and gas piping, pipe flanges, fittings, and automotive components. Their ability to perform under high stress, heat, and pressure makes them great for high-pressure transmission systems and other demanding applications.

Key Characteristics:

- Affordable and easy to machine.

- Excellent mechanical properties, including high heat resistance (up to 900°F) and pressure resistance.

- Impact resistant, offering durability for heavy-duty applications.

Superalloys

Superalloys are forged for the most extreme environments, where temperature stability and mechanical strength are non-negotiable. They are widely used in turbine engines, solar thermal power plants, nuclear reactors, marine equipment, and aerospace components. Their ability to resist oxidation and corrosion makes them indispensable in industries where performance at high temperatures is critical.

Key Characteristics:

- Exceptional mechanical strength and heat resistance, withstanding temperatures between 1,200°F and 1,800°F.

- Resistant to thermal creep deformation, corrosion, and oxidation.

- Highly stable under intense stress and heat.

Learn More About Our Forging Capabilities

Want to know more about what we can do for you? Check out this quick video for a look at our advanced forging processes and the industries we proudly serve. See the difference expertise makes.

Frequently Asked Questions: Materials for Forging Metals

If you want to learn more about materials for forging metals, check out our helpful FAQ for the answers to our most commonly asked questions.

What factors determine the best forging material for a specific application?

The choice of metal forging materials depends on factors such as operating temperature, mechanical stress, corrosion exposure, weight constraints, and cost efficiency. Applications in high-heat environments, for example, require materials like superalloys.

Are industrial forge materials recyclable?

Yes, most metal forging processes allow for material recyclability. Stainless steel and carbon alloys can all be reclaimed and repurposed without losing their integrity. Many industries incorporate sustainable forging practices to reduce waste and improve material efficiency.

How does heat treatment affect forged materials?

Heat treatment toughens the mechanical properties of forged metals by altering their hardness, ductility, and tensile strength. Quenching and tempering are commonly used to increase durability in carbon alloys, and solution treatment and aging are used to optimize the strength of superalloys.

Find the Right Forging Materials for Your Project

Selecting the right forging materials is a big step in your operations. Whether you need high-strength carbon alloys, corrosion-resistant stainless steel, or heat-resistant superalloys, Canton Drop Forge has the expertise to guide you toward the best solution. Our team works closely with you to understand your application, industry standards, and performance requirements—ensuring every forged part meets your specifications. Contact us today to discuss your project.