What Sets Our Alloy Forging Capabilities Apart

Not all alloy forges are capable of the same operations. At Canton Drop Forge, we combine old-school craftsmanship with modern technology to produce forged alloy components that meet today’s toughest specs. Our closed-die forging process allows for exceptional control over shape, strength, and grain flow, resulting in parts that are not only durable but also dimensionally precise.

As one of the most experienced alloy steel forging manufacturers in the U.S., we offer complete in-house capabilities, from die design and machining to heat treatment and inspection. That vertical integration means greater consistency, faster turnaround times, and quality you can count on. Whether you’re looking for alloy steel forgings for high-stress mechanical systems or custom components for a new application, our team delivers the expertise and equipment to make it happen—on time and on spec.

Alloys We Forge: Built for Demanding Environments

The right material makes all the difference, especially when performance, safety, and durability are on the line. Canton Drop Forge works with a wide range of forged alloys, each selected for its specific mechanical properties, corrosion resistance, and performance under load, stress, or temperature extremes.

Alloy Steel Forgings

Known for its superior toughness and fatigue resistance, forged alloy steel is commonly used for shafts, gears, flanges, and high-strength fasteners. By carefully controlling carbon and alloying elements like chromium, molybdenum, and nickel, we produce components that perform consistently in critical applications.

Stainless Steel

Combining strength with excellent corrosion and oxidation resistance, stainless steel is ideal for harsh environments such as marine systems, chemical plants, and food-grade equipment. We forge various stainless grades, including austenitic and martensitic types, depending on the mechanical and thermal demands of the part.

Superalloys

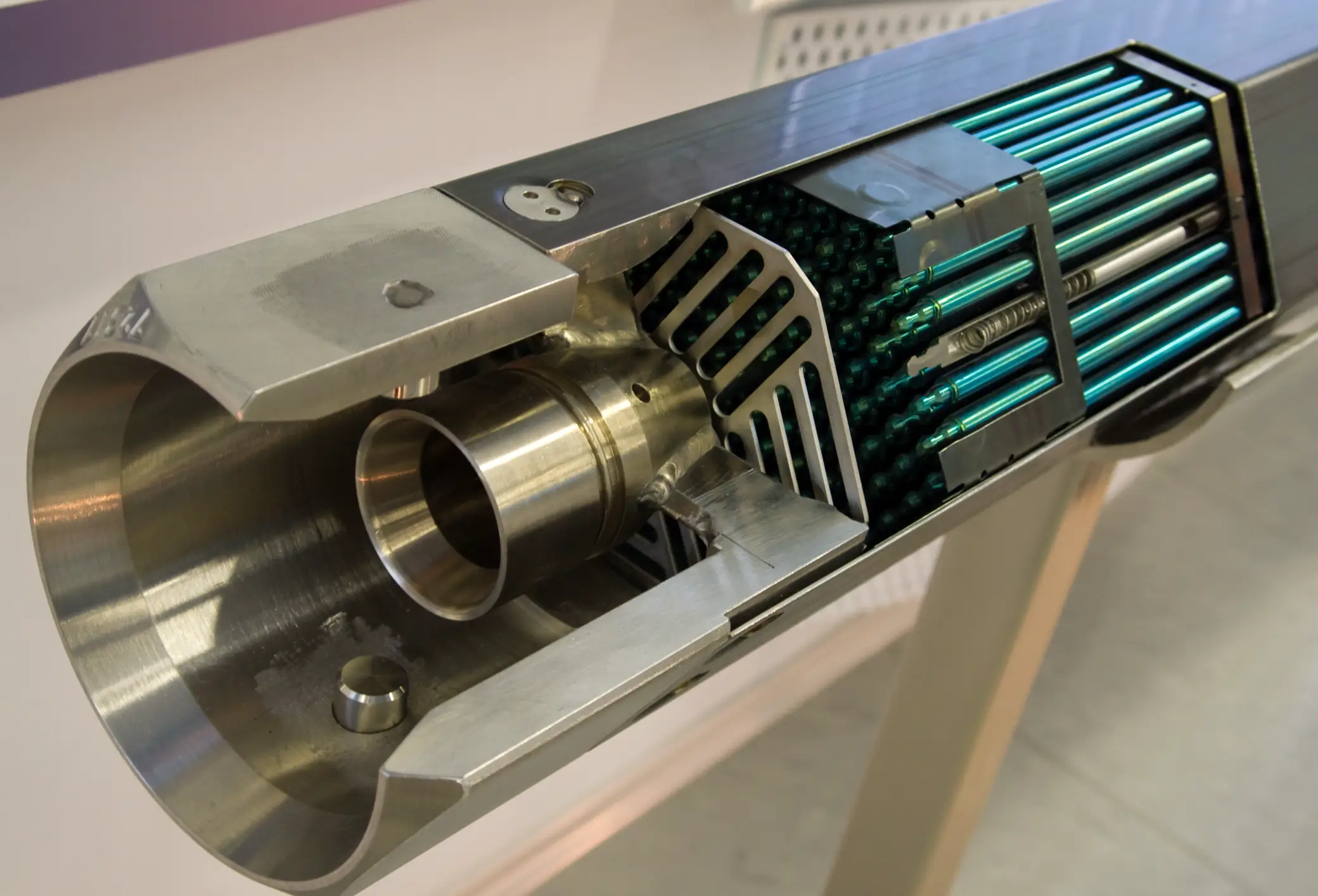

Engineered to maintain structural integrity at temperatures above 1,000°F, superalloys like Inconel®, Hastelloy®, and Waspaloy® are forged for components in jet engines, nuclear reactors, and other high-heat environments. These materials offer exceptional creep resistance, oxidation resistance, and long-term performance under thermal cycling.

All of our alloy steel forgings undergo rigorous quality assurance, including material traceability, mechanical testing, and in-process inspections. You can count on a material that’s engineered not just to meet your specs, but to perform under pressure

Our Forging Equipment and Capabilities

At Canton Drop Forge, we’ve built a reputation on precision, power, and process control. Our advanced alloy forging equipment gives us the flexibility to take on complex geometries, demanding specifications, and both low- and high-volume production runs.

We operate 14 forging hammers, ranging from 3,000 to 50,000 pounds, along with a 1,200-ton hydraulic press, making us one of the most capable alloy steel forging manufacturers in North America. This range of force allows us to efficiently forge a wide variety of part sizes and shapes while maintaining tight tolerances and refined grain flow.

In-house capabilities include:

- Custom die sinking using CNC and EDM equipment

- Precision heat treatment for hardness, ductility, and fatigue resistance

- Comprehensive inspection and testing, including magnetic particle, ultrasonic, and mechanical property testing

From rough blanks to near-net shapes, every forged alloy we produce is backed by rigorous process control and quality standards. Whether you’re developing a single prototype or ramping up for full production, our equipment and expertise ensure consistency from start to finish.

Industries We Serve—and Why They Trust Our Forged Alloy Components

When failure isn’t an option, professionals turn to Canton Drop Forge. Our forged alloy components are engineered to perform in high-stakes industries where strength, precision, and reliability are non-negotiable.

We proudly serve a wide range of sectors, including:

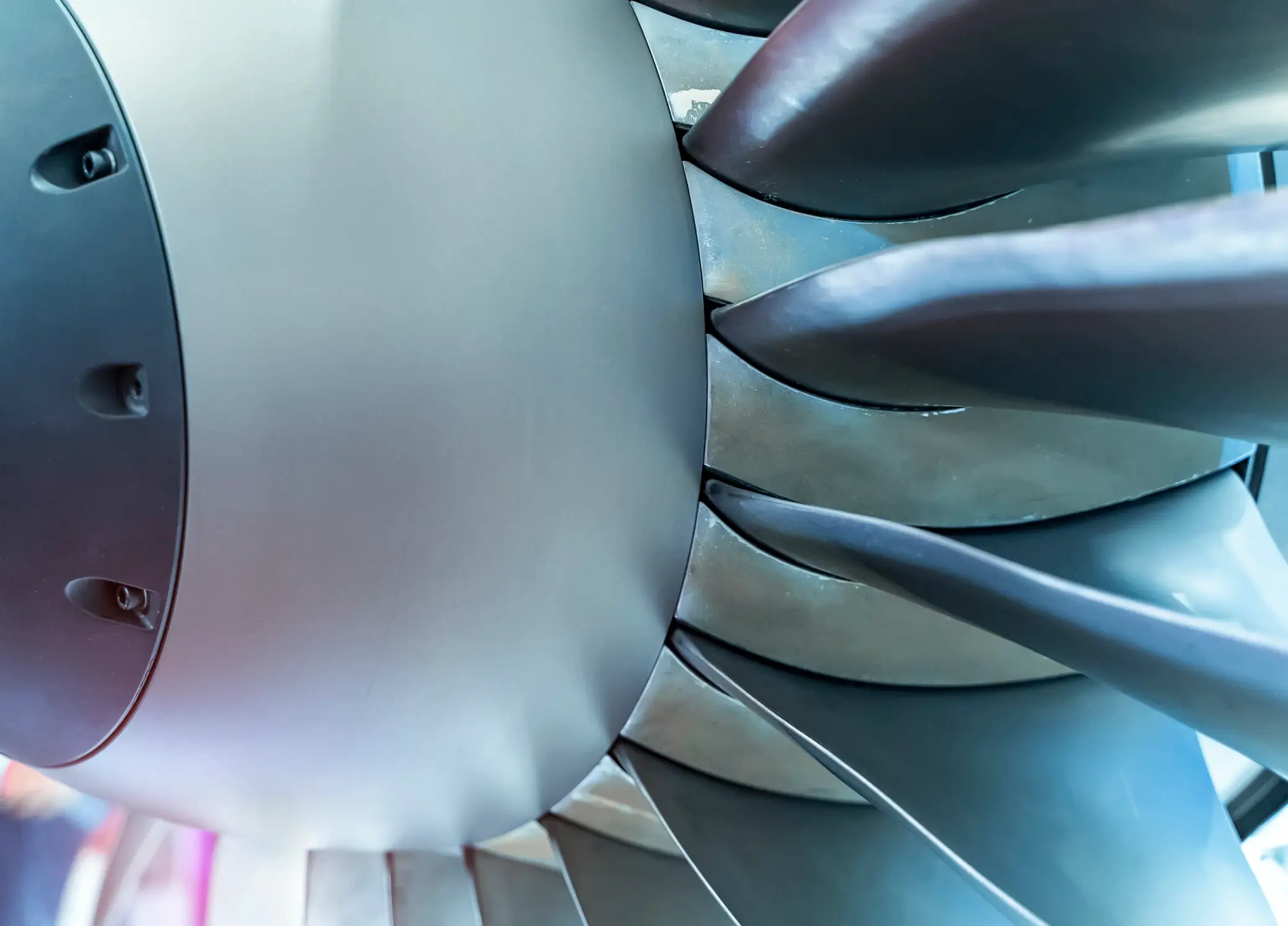

- Aerospace: From landing gear components to engine mounts, our forged alloy steel parts offer the structural integrity and fatigue resistance critical to flight systems.

- Defense & Military: Closed-die forgings are ideal for military-grade hardware, armored vehicle parts, and mission-critical support systems that demand both performance and durability.

- Oil & Gas: Our alloy forge capabilities support upstream, midstream, and downstream operations, producing high-pressure fittings, flanges, and valve bodies built to withstand corrosion, abrasion, and extreme environments.

- Ground Transportation: We supply forged alloy components for heavy trucks, rail systems, and off-highway equipment, helping manufacturers meet strict safety and performance standards.

- Power Generation: Superalloy and stainless steel forgings are used in turbines, pressure vessels, and thermal systems that operate under high temperature and cyclic stress.

- & More

Across all industries, our customers rely on us not just for product performance—but for responsive service, engineering collaboration, and end-to-end quality assurance. No matter the application, we produce alloy forgings designed to perform where it matters most.

Frequently Asked Questions: Alloy Forgings

Need to know more about alloy forgings before getting in touch? Check out our helpful FAQs below for answers to our most frequently asked questions on the topic.

What are the benefits of using alloy steel forgings over cast or machined parts?

Forged alloy steel offers superior strength, impact resistance, and fatigue life compared to cast or machined components. The forging process aligns the metal’s grain flow with the part shape, resulting in improved structural integrity and performance under stress.

Can Canton Drop Forge help with design or material selection for my project?

Yes! Our team offers engineering support throughout the process—from helping you choose the right forged alloy to optimizing the design for strength and manufacturability. We’re here to make sure your component performs exactly as needed.

What’s the difference between a general forge and an alloy forge?

A general forge may handle a broad range of metals, while an alloy forge like Canton Drop Forge specializes in forging engineered metal blends designed for enhanced mechanical properties. This specialization allows for better control, consistency, and performance of alloy forgings.

Ready to Start Your Alloy Forging Project?

Whether you’re in the early design phase or finalizing specs for production, Canton Drop Forge is ready to help you bring your forged alloy component to life. With over a century of forging expertise, industry-leading equipment, and a commitment to precision, we’re trusted by manufacturers and engineers across the country for reliable, high-performance alloy forgings.

Let’s talk about your project. Contact us today to request a free quote, discuss your requirements, or explore how our alloy forging capabilities can support your next build. When you work with Canton Drop Forge, you’re not just getting a part—you’re getting a partner.